Type:

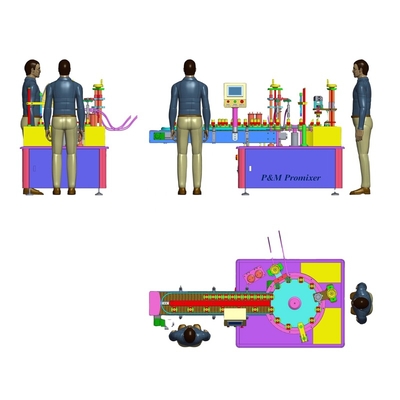

Filling Machine

Applicable Industries:

Manufacturing Plant

Showroom Location:

Spain

Condition:

New

Application:

Food, Liquid Paste

Packaging Type:

Bottles, CANS

Packaging Material:

Plastic, Wood

Automatic Grade:

Automatic

Driven Type:

Pneumatic

Voltage:

220V/380V

Dimension(L*W*H):

In Kind Prevail

Weight:

KG

Warranty:

1 Year

Key Selling Points:

Sustainable

Machinery Capacity:

Other

Filling Material:

Other, Water

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

2 Years

Core Components:

Pump, Other, PLC

Name:

Filling Machine

Filling Frame Material:

Stainless Steel 304

Filling Head Material:

Stainless Steel 316L

Filling Form:

Servo Drive Piston Filling

Filling Speed:

1800-2000 Bottles/hour(400ml/h)

Filling Accuracy:

0.5%

Control:

PLC

Protector:

Alarm Of Liquid Storage Tank

Filling Motor:

Servo Motor

Function:

Filling

After Warranty Service:

Video Technical Support, Online Support, Spare Parts

Local Service Location:

Turkey, Italy, Spain

After-sales Service Provided:

Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

Certification:

CE Certificate

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!